SYSTEM KAN-therm

Rail

PipesFor surface heating and cooling installations, KAN provides a wide range of pipes, both as far as diameters and types are concerned. This makes it possible to select a technically and economically optimal solution, at the same time meeting all customer requirements.

To make surface heating and cooling instillations (underfloor, wall, ceiling), two main KAN‑therm pipes are recommended - polyethylene pipes with EVOH layer and pipes with AL layer.

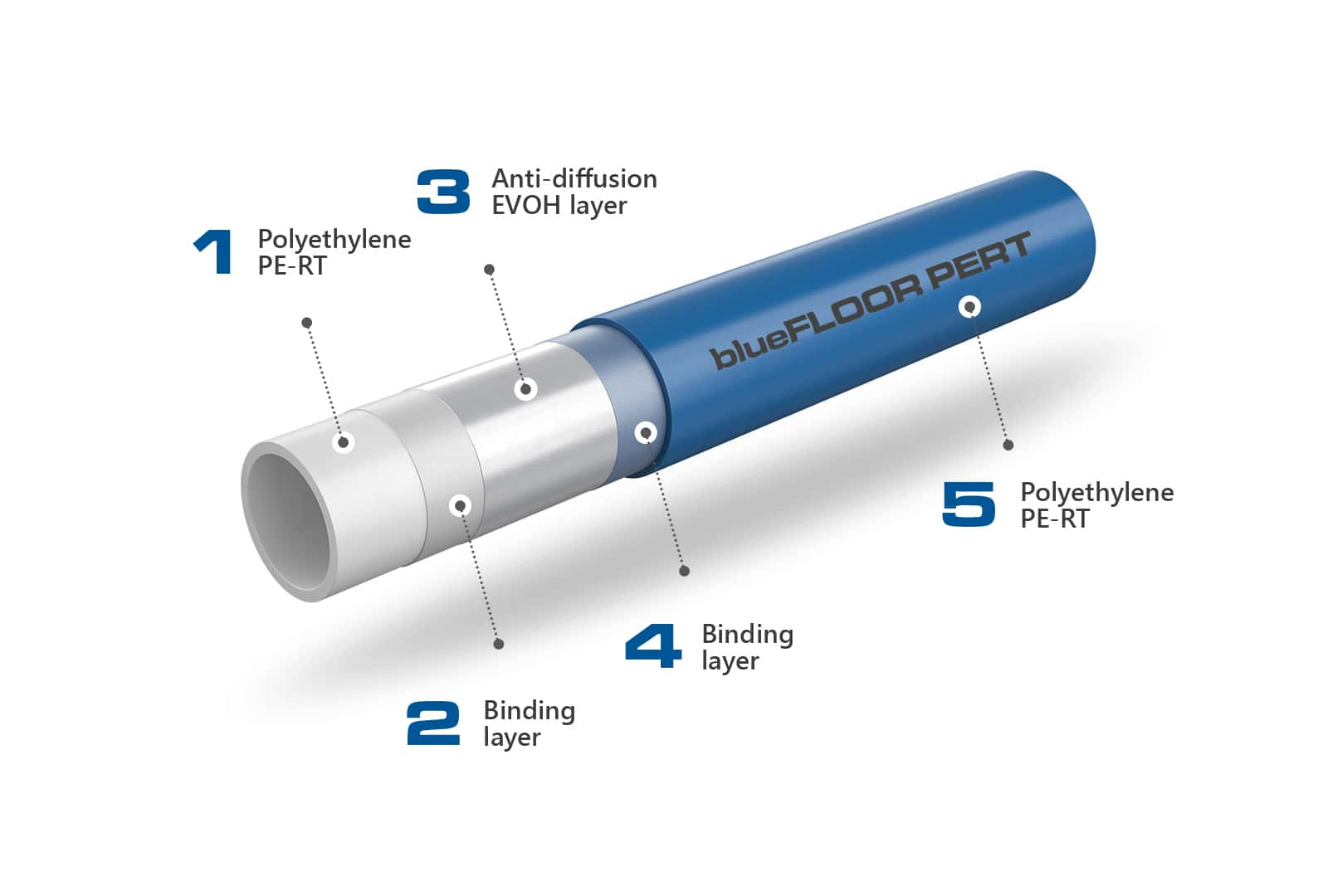

KAN‑therm bluePERT are high-grade pipes with EVOH layer designed for making surface heating and cooling installations (application class 4 according to ISO 10508).

The pipes are made in the five-layer (5L) technology, where all layers are permanently combined in the production process.

Thanks to the use of PE-RT polyethylene (type I) with high thermal resistance and the high flexibility of the product, KAN‑therm bluePERT pipes are comfortable to install even at low temperatures.

The EVOH anti-diffusion layer guarantees tightness against oxygen ingress into the system, protecting its components against corrosion.

The EVOH anti-diffusion layer (ethyl vinyl alcohol) meets the requirements of DIN 4726.

The pipes are made in line with PN‑EN ISO 21003.

KAN‑therm bluePERT pipes are available in the diameter range of 12-25mm.

They are offered in standard coils of 200 or 300m.

KAN‑therm bluePERT pipes in long coils of 600mb are an additional offer. This coil length significantly increases the convenience of installing heating loops and prevents creating short pipe sections that are difficult to use.

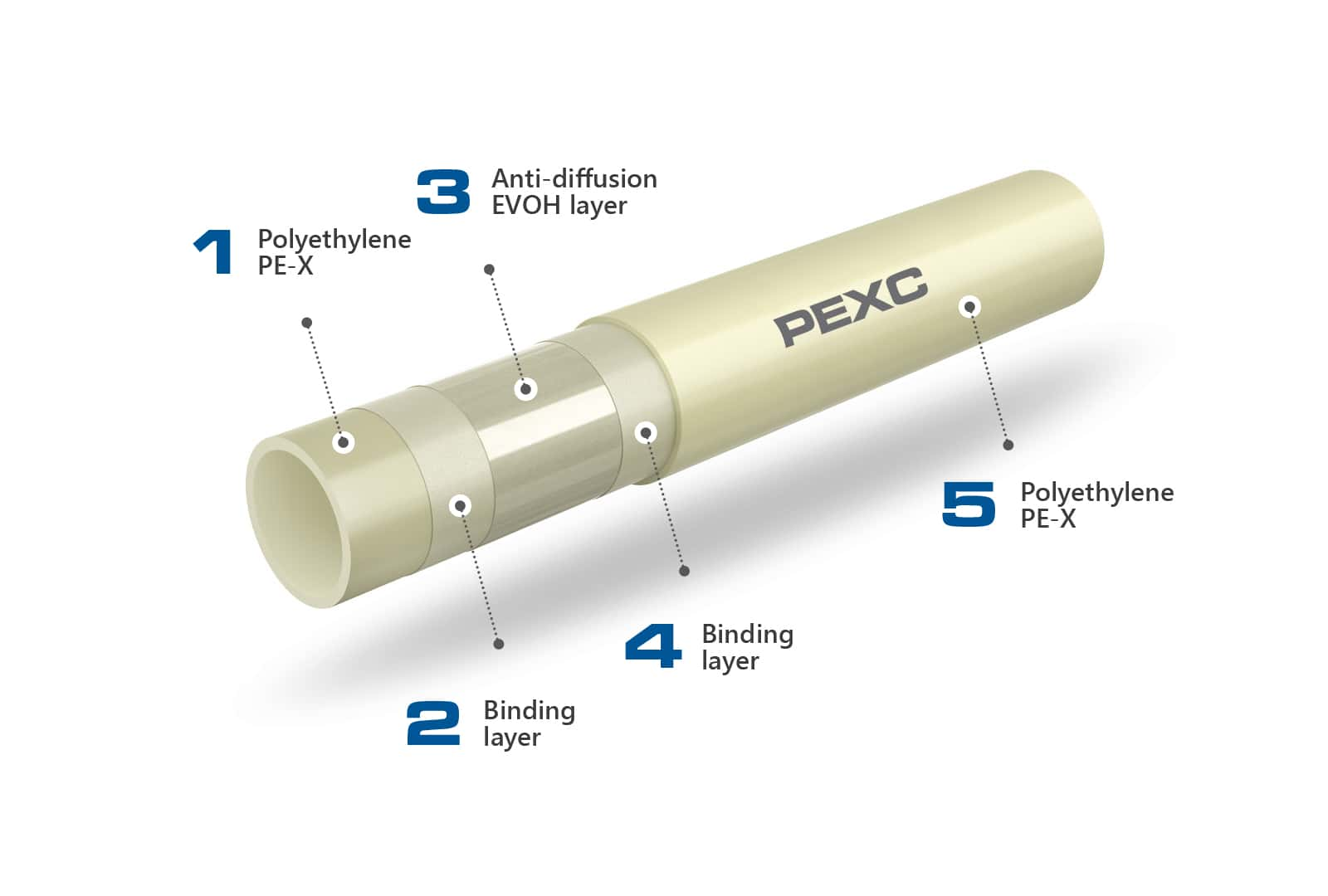

Universal PEXC, PERT or polybutylene pipes (type II) with EVOH layer, available in the offer of system KAN‑therm, can also be used to make surface heating and cooling installations. PEXC and PERT pipes are also made in the five-layer construction (5L) and available in the diameter range of 12 to 25mm.

Polybutylene pipes (PB) are available in the diameter of 8mm.

The five-layer (5L) construction of the bluePERT, PEXC and PERT pipes secures the EVOH anti-diffusion layer against damage during the assembly works.

PEXC pipes - are made of polyethylene which undergoes a strengthening process (cross-linking) at the final stage of the pipe production. The process utilises the safest cross-linking method in terms of hygiene (no chemical additives in the production process) and the most effective one – type "c". It consists in "bombarding" the previously manufactured pipe by a beam of electrons, which results in a change in the molecular structure of polyethylene and as a result increases the service life of the finished product.

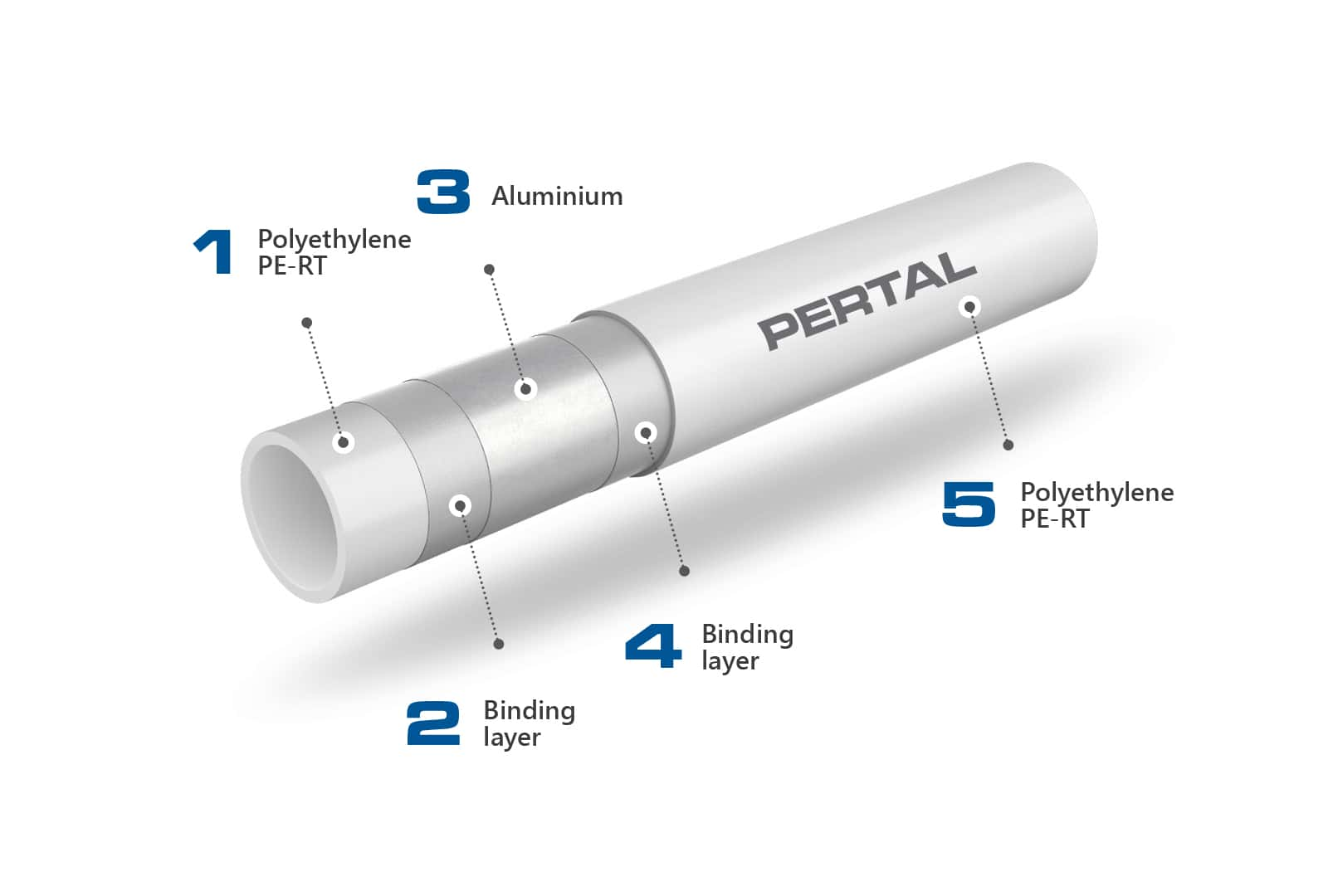

PERTAL pipes are another type of pipes that can be used to lay an installation supplying KAN‑therm Wall heating and cooling panels. These are universal polyethylene pipes, made in a multilayer construction with the use of an aluminium layer (application class 1-5 according to ISO 10508).

The butt-welded aluminium layer, using laser technology, acts as an anti-diffusion coating and guarantees the tightness against oxygen ingress into the system, protecting its components against corrosion.

The pipes are made in line with PN‑EN ISO 21003.

PERTAL pipes are available in the diameter range of 16-20mm. They are offered in standard coils of 200 or 100rm. The most popular diameters are also available in 600rm coils.

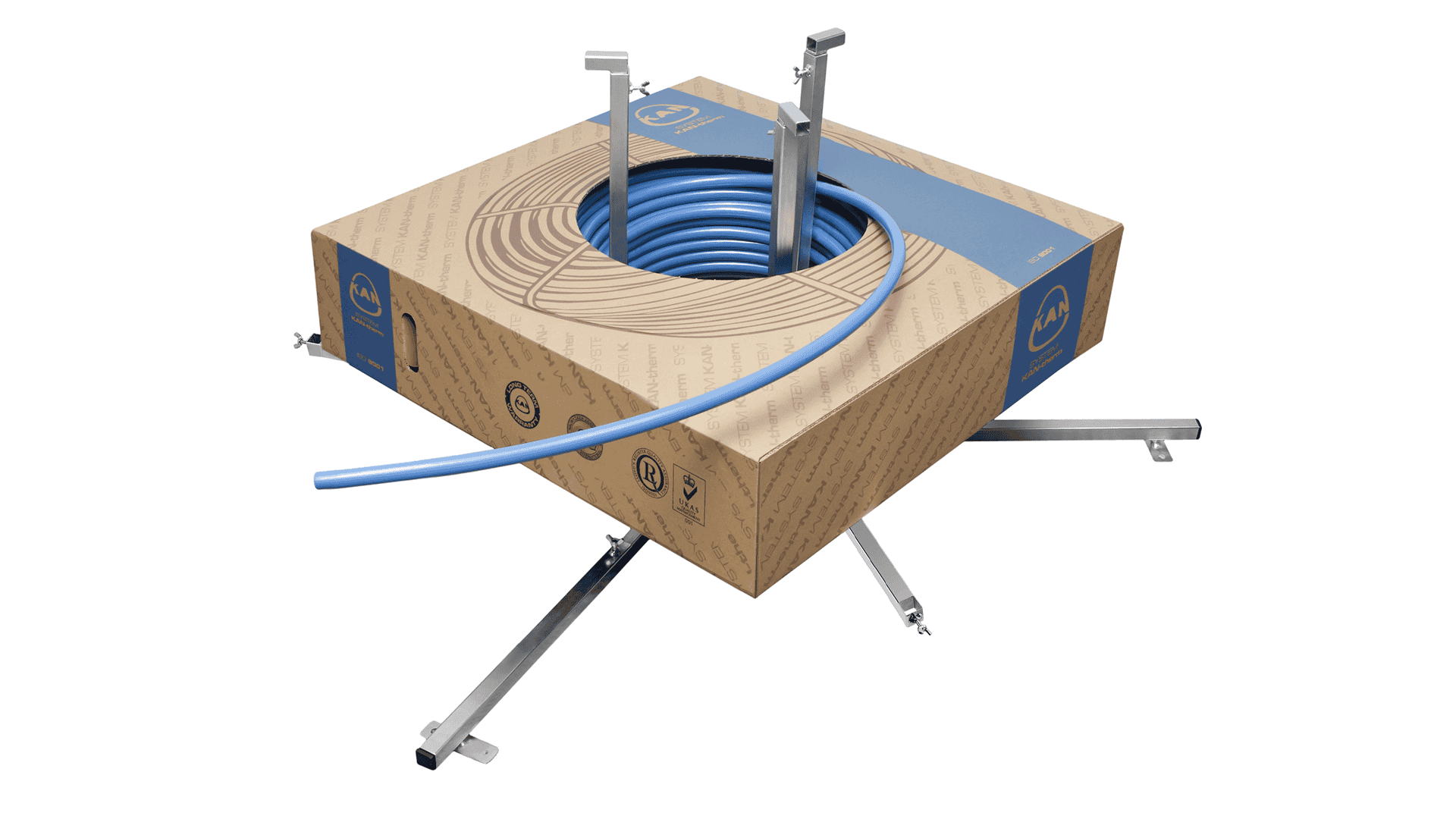

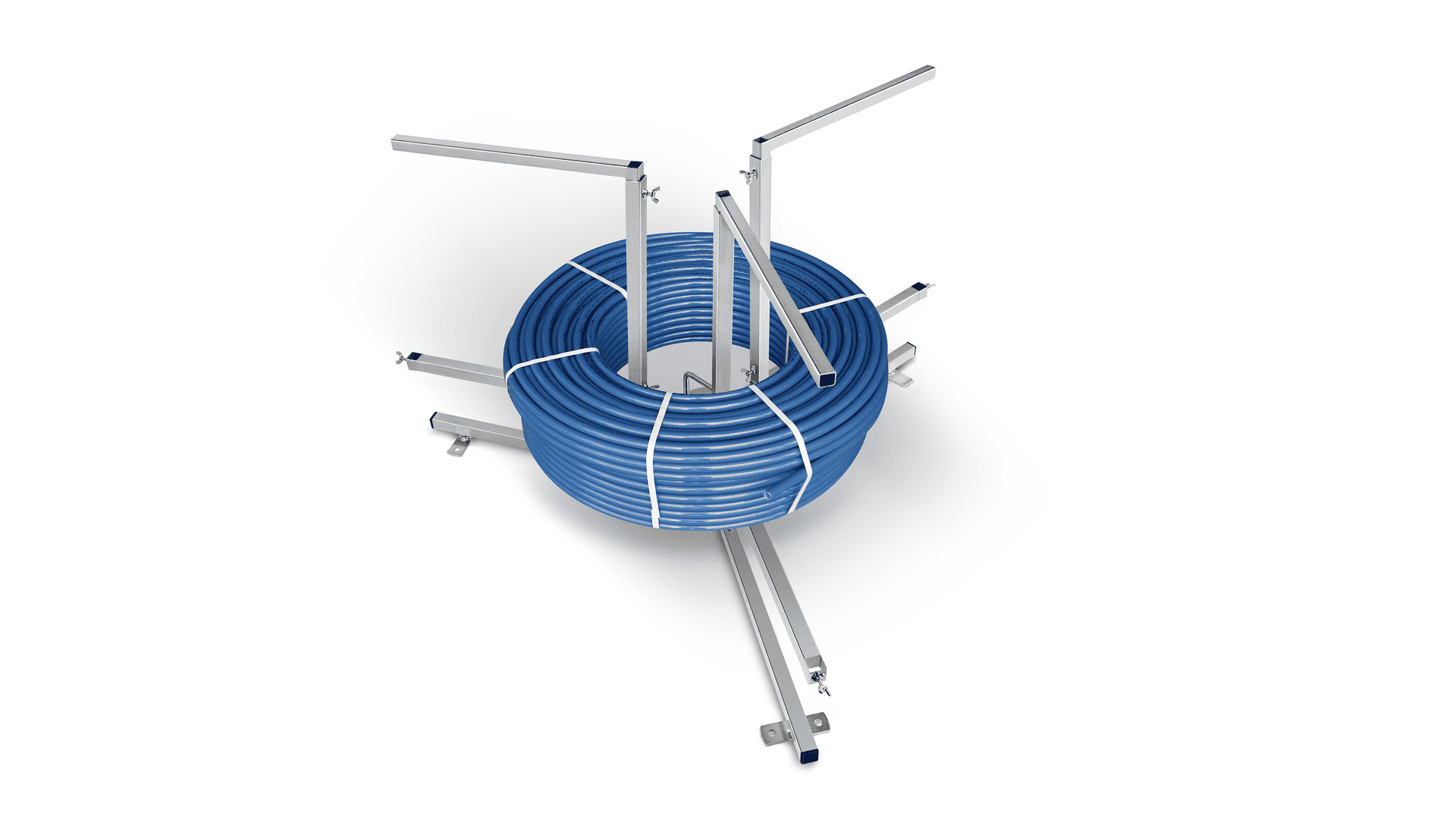

Assembly of heating loops made of KAN-therm pipes supplied in coils is much easier with the use of a special pipe decoiler.

Specially prepared cartons make it possible to install the system without taking the pipe out of the packaging.

The possibility of adjusting the decoiler makes it possible to work also with long pipe coils, so that work is faster and more comfortable.

Cookies settings

We use cookies to provide a variety of services, to continuously improve our services, to display advertisements according to your interests on our website and to provide social media features. Some cookies are necessary for the proper functioning of our website and to enable you to use its functions. With your consent, we also use analytical cookies to improve our website and marketing cookies to display advertisements and content on our website. Learn more about cookies and how to use them.

By clicking “Accept all", you consent to the use of all cookies. By clicking "Customise cookie settings", you can choose which cookies you accept. You can change your cookie settings or withdraw your consent at any time.

Cookies settings

This tool helps to select and deactivate the various tags/trackers/analytics tools used on this website.

-

Services required

These technologies are required to activate the basic functionality of the website.

Clickmeeting

Freshmail

YouTube Video

GrafiteCMS

erecruiter

-

Marketing services

These technologies are used by advertisers to display advertisements that match your interests.

Facebook Pixel

Facebook Social Plugins

-

Analytical services

These technologies allow us to analyse website usage in order to measure and improve performance.

Google Tag Manager

Google Ads

Google Ads Conversion Tracking

SmartLook

AddThis

Yandex Metrica

Google Maps

Google Analytics

The provision of personal data is voluntary, although necessary for the proper operation of your account and all the functionalities associated with it. Information about the user’s rights, including the right to access the content of data, rectification, erasure, restriction of processing, data portability, object, withdraw consent at any time without affecting the lawfulness of the processing and to lodge a complaint with the supervisory authority for data protection is further specified in:

Privacy policy Rules of electronic services provision-

Facebook Pixel

Marketing services

Service description

This is Tracking technology offered by Facebook and used by other Facebook services such as Facebook Custom Audiences.

Processing entity

Facebook Ireland Limited

4 Grand Canal Square, Grand Canal Harbour, Dublin, D02, IrelandPurposes of data processing

This list shows the purposes of data collection and processing.

Facebook function integration

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Pixel

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

European Union

Polska

Useful

Terms and conditions, privacy policy.

Art. 6 ust. 1 pkt. 1 lit. a GDPR

-

Google Tag Manager

Analytical services

Service description

This is a tag management system. The user can update measurement codes and related code parts, collectively known as tags, on the user's website or mobile app.

Processing entity

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Clickmeeting

Services required

Service description

A service used to organise online meetings and live webinars.

Processing entity

ClickMeeting sp. z o.o.; Gdańsk, Poland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://clickmeeting.com/pl/legal

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Freshmail

Services required

Service description

E-mail marketing services are provided via the website.

Processing entity

FreshMail Holding S.A.; Kraków, Poland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://freshmail.com/privacy-policy-2/

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Ads

Analytical services

Service description

This is an advertising service.

Processing entity

Google Ireland Limited Google Building Gordon House, 4 Barrow Street, Dublin D04 E5W5, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Ads Conversion Tracking

Analytical services

Service description

This is a conversion tracking service.

Processing entity

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

SmartLook

Analytical services

Service description

Processing entity

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

-

YouTube Video

Services required

Service description

Processing entity

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

-

Facebook Social Plugins

Marketing services

Service description

This is a Facebook social plug-in that enables you to integrate Facebook content with third-party websites.

Processing entity

Facebook Ireland Limited 4 Grand Canal Square, Grand Canal Harbour, Dublin, D02, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://www.facebook.com/policies/cookies/

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

AddThis

Analytical services

Service description

Processing entity

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

-

Yandex Metrica

Analytical services

Service description

Processing entity

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

-

Google Maps

Analytical services

Service description

This is a web-mapping service.

Processing entity

Google Ireland Limited Gordon House, 4 Barrow St, Dublin 4, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Analytics

Analytical services

Service description

This is a web analytics service. This enables the user to measure ROI from advertising, as well as tracking Flash, video and social media websites and apps.

Processing entity

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

GrafiteCMS

Services required

Service description

A powerful independent CMS for Laravel applications.

Processing entity

Grafite Inc., 777 Waterloo St, Mount Forest, ON N0G 2L3, Canada

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://opensource.org/licenses/MIT

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

erecruiter

Services required

Service description

Processing entity

eRecruitment Solutions sp. z o.o. Group Pracuj SA

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci