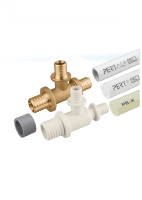

KAN‑therm ultraLINE fittings are versatile and so they can connect different types of pipes, i.e. PEXC, PERT² and PERTAL². This unique feature makes sure that the final solution can be configured as desired.

The biggest advantage of the ultraLINE fittings is their construction without O-rings.

No additional sealing means easier assembly, and what is most important, lower risk of damaging the connection.

Fittings have specially shaped connectors (without additional seals), which are inserted into the previously expanded end of the pipe and then slid onto the connection with a plastic sleeve. The pipe is clamped circumferentially on the coupling stub in the entire contact plane. Such a connection allows for conducting the installation in structural partitions (in flooring finishing coats and under layers of plaster) without any limitations.

Sliding sleeves of system KAN‑therm ultraLINE are one of the most important elements responsible for connecting and sealing the pipe with the fitting.

The sleeves are produced only of high-quality PVDF.

Their symmetrical design is a nod to individuals and contractors.

The mounting of the sleeve on the pipe is arbitrary, no specific positioning is required. This is a great convenience for installers and a guarantee of correctly made connections.

The ultraLINE construction sets new standards in installation.

ultraLINE fittings mean over 30 years of experience on the market, constant research and development aimed at creating a product that is safe, convenient and resistant to the most common defects in workmanship.

ultraLINE is the vision come true of a perfect product that symbolises and sets the latest trends in the installation technology.

Advantages of the ultraLINE construction:

- wide range of fittings and connectors with threads,

- application versatility making it possible to use brass and plastic elements practically in any type of installation,

- wide range of plastic elements (PPSU) that guarantee price optimisation of the complete investment and protecting the installation against the negative effects of water with an unfavourable chemical composition,

- universal design of threaded couplings ensuring safe and tight connection with various types of pipes,

- design of elements in diameters of 25 and 32mm with increased internal cross-section, which significantly increases the hydraulics and makes it possible to perform the so-called hydraulic optimisation of the designed installation,

- sound-proofing elements for installations available as standard,

- aesthetic look of fittings and light colour of PPSU plastic structures significantly increases the visibility of the element in dark rooms,

- symmetrical construction of the sliding sleeves minimises the risk of mistakes and significantly increases comfort during installation.

ultraLINE threaded connections

To connect System KAN-therm ultraLINE pipes, in addition to connections with a sliding sleeve, standard threaded connections with a flat wrench can be used.

Two main types of connectors are available for these connectors:

- union connectors

- threaded couplings

Union connectors

Universal ultraLINE union connections are available in the diameter range of 14-20mm.

Real advantage of union connections is their automatic sealing after fitting. Connections of this kind are self-sealing and need no additional seal, such as Teflon tape or tow.

The connections should be located in easily available spaces.

Threaded couplings and connectors

Universal threaded couplings with internal, external threads or so-called connectors, available in diameters 14-20mm.

Threaded couplings from the pipe connection side do not require the use of additional seals – tightness is guaranteed by the appropriate construction of the coupling stub on which the pipe is mounted. From the thread side (internal or external) an additional sealing in the form of tow should be used.

Threaded couplings, due to the specificity of the fitting and its design, do not require additional sealing.

Threaded connections must be located in easily available spaces.

Threaded couplings and union connections have a construction making it possible to assembly at the same time uniform PEXC and PERT² pipes and PERTAL² pipes.

Thanks to the universal structure of couplings and union connections, duplicating the fitting offer is avoided, which translates into more flexible and comfortable installation, as well as saving space for storing elements.

Cookies settings

We use cookies to provide a variety of services, to continuously improve our services, to display advertisements according to your interests on our website and to provide social media features. Some cookies are necessary for the proper functioning of our website and to enable you to use its functions. With your consent, we also use analytical cookies to improve our website and marketing cookies to display advertisements and content on our website. Learn more about cookies and how to use them.

By clicking “Accept all", you consent to the use of all cookies. By clicking "Customise cookie settings", you can choose which cookies you accept. You can change your cookie settings or withdraw your consent at any time.

Cookies settings

This tool helps to select and deactivate the various tags/trackers/analytics tools used on this website.

-

Services required

These technologies are required to activate the basic functionality of the website.

Clickmeeting

Freshmail

YouTube Video

GrafiteCMS

erecruiter

-

Marketing services

These technologies are used by advertisers to display advertisements that match your interests.

Facebook Pixel

Facebook Social Plugins

-

Analytical services

These technologies allow us to analyse website usage in order to measure and improve performance.

Google Tag Manager

Google Ads

Google Ads Conversion Tracking

SmartLook

AddThis

Yandex Metrica

Google Maps

Google Analytics

The provision of personal data is voluntary, although necessary for the proper operation of your account and all the functionalities associated with it. Information about the user’s rights, including the right to access the content of data, rectification, erasure, restriction of processing, data portability, object, withdraw consent at any time without affecting the lawfulness of the processing and to lodge a complaint with the supervisory authority for data protection is further specified in:

Privacy policy Rules of electronic services provision-

Facebook Pixel

Marketing services

Service description

This is Tracking technology offered by Facebook and used by other Facebook services such as Facebook Custom Audiences.

Processing entity

Facebook Ireland Limited

4 Grand Canal Square, Grand Canal Harbour, Dublin, D02, IrelandPurposes of data processing

This list shows the purposes of data collection and processing.

Facebook function integration

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Pixel

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

European Union

Polska

Useful

Terms and conditions, privacy policy.

Art. 6 ust. 1 pkt. 1 lit. a GDPR

-

Google Tag Manager

Analytical services

Service description

This is a tag management system. The user can update measurement codes and related code parts, collectively known as tags, on the user's website or mobile app.

Processing entity

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Clickmeeting

Services required

Service description

A service used to organise online meetings and live webinars.

Processing entity

ClickMeeting sp. z o.o.; Gdańsk, Poland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://clickmeeting.com/pl/legal

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Freshmail

Services required

Service description

E-mail marketing services are provided via the website.

Processing entity

FreshMail Holding S.A.; Kraków, Poland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://freshmail.com/privacy-policy-2/

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Ads

Analytical services

Service description

This is an advertising service.

Processing entity

Google Ireland Limited Google Building Gordon House, 4 Barrow Street, Dublin D04 E5W5, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Ads Conversion Tracking

Analytical services

Service description

This is a conversion tracking service.

Processing entity

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

SmartLook

Analytical services

Service description

Processing entity

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

-

YouTube Video

Services required

Service description

Processing entity

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

-

Facebook Social Plugins

Marketing services

Service description

This is a Facebook social plug-in that enables you to integrate Facebook content with third-party websites.

Processing entity

Facebook Ireland Limited 4 Grand Canal Square, Grand Canal Harbour, Dublin, D02, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://www.facebook.com/policies/cookies/

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

AddThis

Analytical services

Service description

Processing entity

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

-

Yandex Metrica

Analytical services

Service description

Processing entity

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

-

Google Maps

Analytical services

Service description

This is a web-mapping service.

Processing entity

Google Ireland Limited Gordon House, 4 Barrow St, Dublin 4, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Analytics

Analytical services

Service description

This is a web analytics service. This enables the user to measure ROI from advertising, as well as tracking Flash, video and social media websites and apps.

Processing entity

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Ireland

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://policies.google.com/privacy?hl=en

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

GrafiteCMS

Services required

Service description

A powerful independent CMS for Laravel applications.

Processing entity

Grafite Inc., 777 Waterloo St, Mount Forest, ON N0G 2L3, Canada

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

https://opensource.org/licenses/MIT

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

erecruiter

Services required

Service description

Processing entity

eRecruitment Solutions sp. z o.o. Group Pracuj SA

Purposes of data processing

This list shows the purposes of data collection and processing.

Processing information by the processing entity

The link below provides information about the data collected when using this particular service. This could be data such as IP, data retention time or data of the company providing the service.

Technologies used

This list shows all the technologies used by this service to collect data. Typical technologies are cookies and pixels, which are placed in the browser.

Legal basis

The necessary legal basis for data processing is listed below.

Article 6(1) (1)(a) GDPR

Processing location

This is the main location where collected data is processed. If data is also processed in other countries, the user is informed separately.

Useful

Terms and conditions, privacy policy.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci