Underfloor heating is now a standard offered by the world's top developers. A warm floor acts as a large-format radiator, making it most pleasant to walk around the house barefoot. Underfloor heating with the KAN-therm system can turn any, new or existing building into a real dream home.

Asking questions about underfloor heating can help you decide on the best heating system for your home for energy efficiency and thermal comfort. Apart from health and hygiene considerations and ease of use, it will increase the value of the property.

The content below summarises the most frequently asked questions by our customers about underfloor heating. They will help structure the information and make it easier to find answers to questions that may arise in relation to KAN-therm products.

What are the benefits of underfloor heating?

Surface heating provides the optimum and healthiest indoor temperature distribution. This is the most commonly chosen option, where it is warmest near the floor, while the higher parts of the interior are slightly cooler. Wall and ceiling heating also have their advantages. Surface heating systems are cheaper and more comfortable to operate than radiator heating, they are also trouble-free, environmentally friendly and versatile – we can heat any building, both new and retrofitted, in this way.

Radiators or underfloor heating? Which solution is more economical?

The numbers speak in favour of installing underfloor heating with the KAN-therm system. By lowering the air temperature in the home by just 1°C and maintaining full thermal comfort, we can reduce heating costs by at least 5%. After just two years of operating the system, we can expect the investment costs to pay off and therefore achieve greater savings. KAN-therm surface heating and cooling systems have a 10-year guarantee which means a minimum of a decade of trouble-free operation.

To whom are KAN-therm systems dedicated?

The benefits of the system can, of course, be enjoyed by all members of the household, but its benefits will be particularly appreciated by parents of young children who love to play on the floor.

Secondly, people who are unwell in the cold and are willing to wear socks...even in the summer.

Thirdly, aesthetes and design enthusiasts who value aesthetics and functionality, with no visible pipes or radiators. Ultimately, those with allergies should look out for the system as it provides even heat distribution and reduces the circulation of dust in the room compared to traditional radiators.

Can I afford KAN-therm systems?

If you can afford a standard heating solution that you will be operating for decades to come (including servicing, replacing consumable parts and the rising cost of traditional fuel), you can certainly afford the KAN-therm system. Although the cost of purchasing and installing a surface heating system is slightly higher than that of older heat sources, subsequent operation is considerably cheaper. The charges will be reduced not only because of the faultlessness of the KAN-therm System, but also because of the fuel used. Using renewable energy for your own needs is selfish in a healthy way. This way, we are not only thinking about ourselves, low bills and savings, but also about the environment.

What if I want to install the KAN-therm system in an older building?

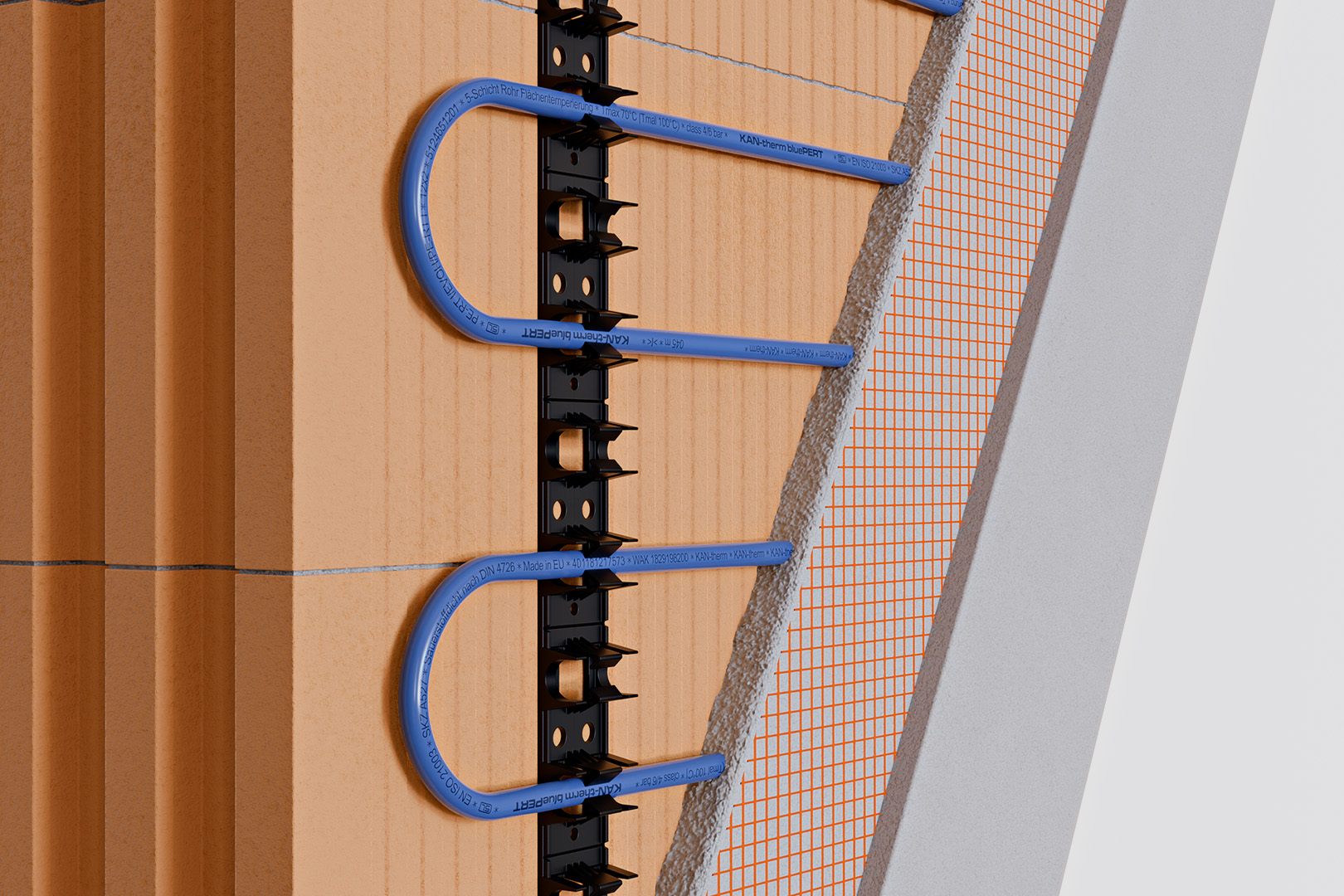

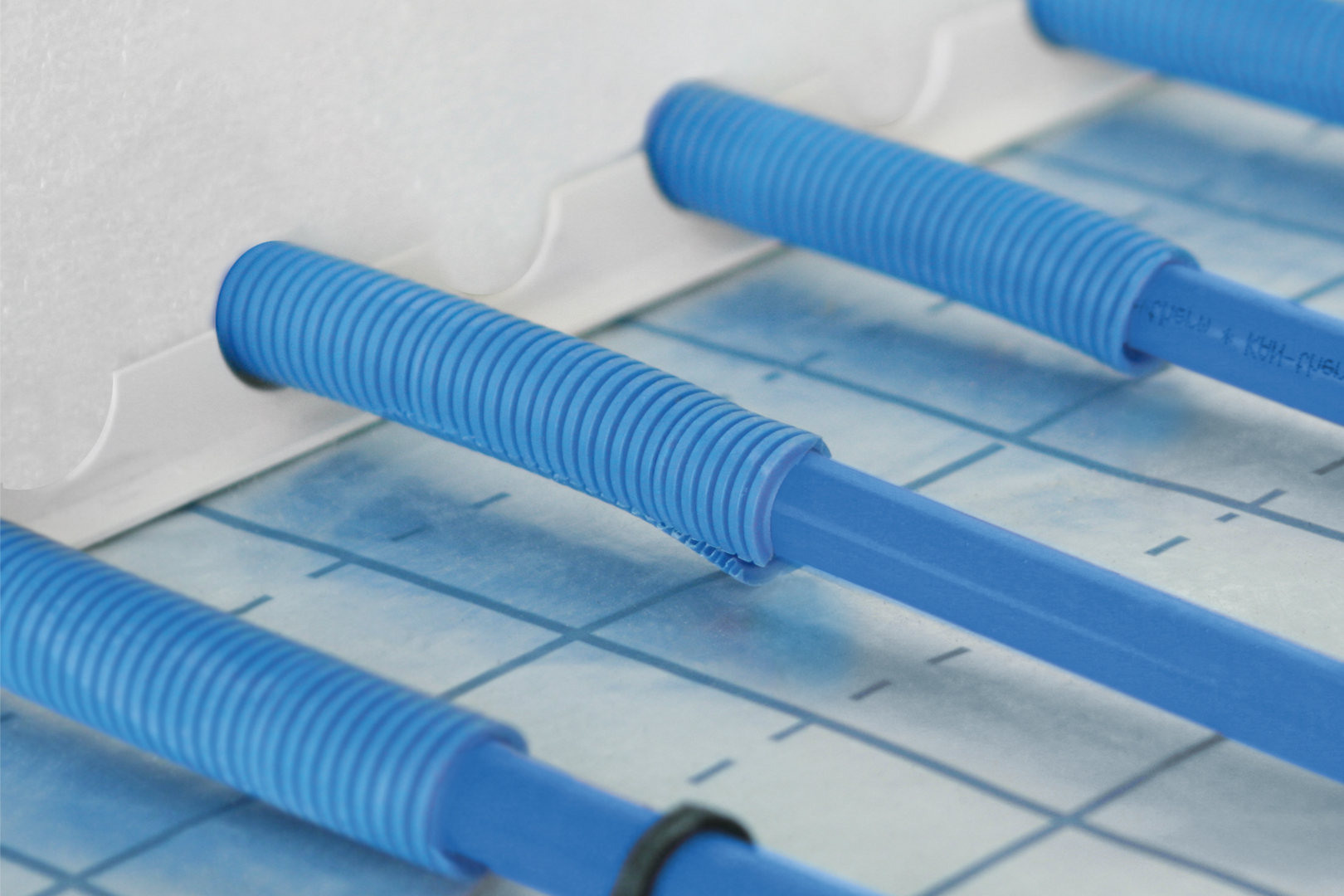

Installing the KAN-therm system in an older building is not a problem. Thanks to the flexible pipes, which you can easily lay under the floor or in the walls, the installation can be carried out without problems even in old buildings. In the case of older buildings, however, it is worth consulting a professional who can advise on the work that needs to be done to ensure that the installation is installed in a safe and effective way. It is also worth bearing in mind that the installation of a flooring system can affect the height of the floor, which can make a difference when choosing doors or furniture, for example.

Can I also use the KAN-therm system in the off-season?

Yes, KAN-therm systems work all year round. During winter, they will provide pleasant warmth, and in summer, they effectively lower the interior temperature to prevent heat. What is more, by easily modifying the heat source, the system's heating capacity can be used for cooling on hot days. Simply switch the heating source to a cooling source, and the same pipes that previously circulated hot water will flow cool water, lowering the room temperature. With the KAN-therm system, you can always enjoy a comfortable temperature in your home or workplace.

How long do I have to wait for the floor to warm up to the right temperature?

In fact ... you don't have to wait at all! All you have to do is set the right temperature in the evening so that you can walk across the warm floor in the morning. You can also issue a command via your smartphone before you leave work to get the system working, and when you return home, your home will already be properly heated. The specific time it takes for the floor to warm up to the desired temperature depends on a number of factors, such as the type of floor, the thermal insulation of the room, the ambient temperature and other.

If you are considering modern technology then the KAN-therm SMART floor automation system comes in handy. The reliability and efficiency you expect from heating systems should correspond with their ease of operation. Also, from anywhere on Earth. All you need is the internet and the right app. Operation of the system is easy, convenient and intuitive, allowing for quick and hassle-free use.

Can I buy an automatic control unit for an installation that has been operating for several years?

Yes! It's never too late to start controlling the temperature in your home! Dedicated KAN-therm SMART automation will be used for this purpose.

- No problematic cabling,

- Fast and efficient,

- And most importantly, clean!

KAN-therm SMART uses radio signal. And it can be set up using a mobile phone or tablet.