Three decades of experience and innovation

KAN-therm products have been on the market for more than three decades. During this time, KAN-therm has developed high standards of quality and manufacturing processes, with each stage of the product life cycle subjected to strict control. The effect? A broad portfolio of innovative solutions and numerous certifications that crown the development of a trusted, socially responsible brand.

KAN-therm ultraPRESS system: Brass or PPSU?

KAN-therm ultraPRESS is one of the most popular piping systems. The fittings currently come in two versions – with a PPSU body or a brass body. Now you can choose your preferred sanitary installation solution, with one or mixed materials.

The practice for making connections with the KAN-therm ultraPRESS system can be described in simple terms: “Cut the pipe perpendicular to the centreline, insert it so that it is visible in the inspection holes, and then make the pressing.”

The connection is made faster than with the traditional pipe pressing process, as you can skip the chamfering of the inner pipe edge.

Compliance with the 4MS Common Approach

Of additional note is the fact that all brass fittings available in the KAN-therm ultraPRESS system range meet the 4MS Common Approach requirements to eliminate heavy metals from drinking water.

The body of the connectors, made of high-quality, zinc loss resistant brass with a low content of heavy metals – including nickel – ensures chemical inertness in contact with drinking water.

High strength and compatibility of KAN-therm ultraPRESS fittings

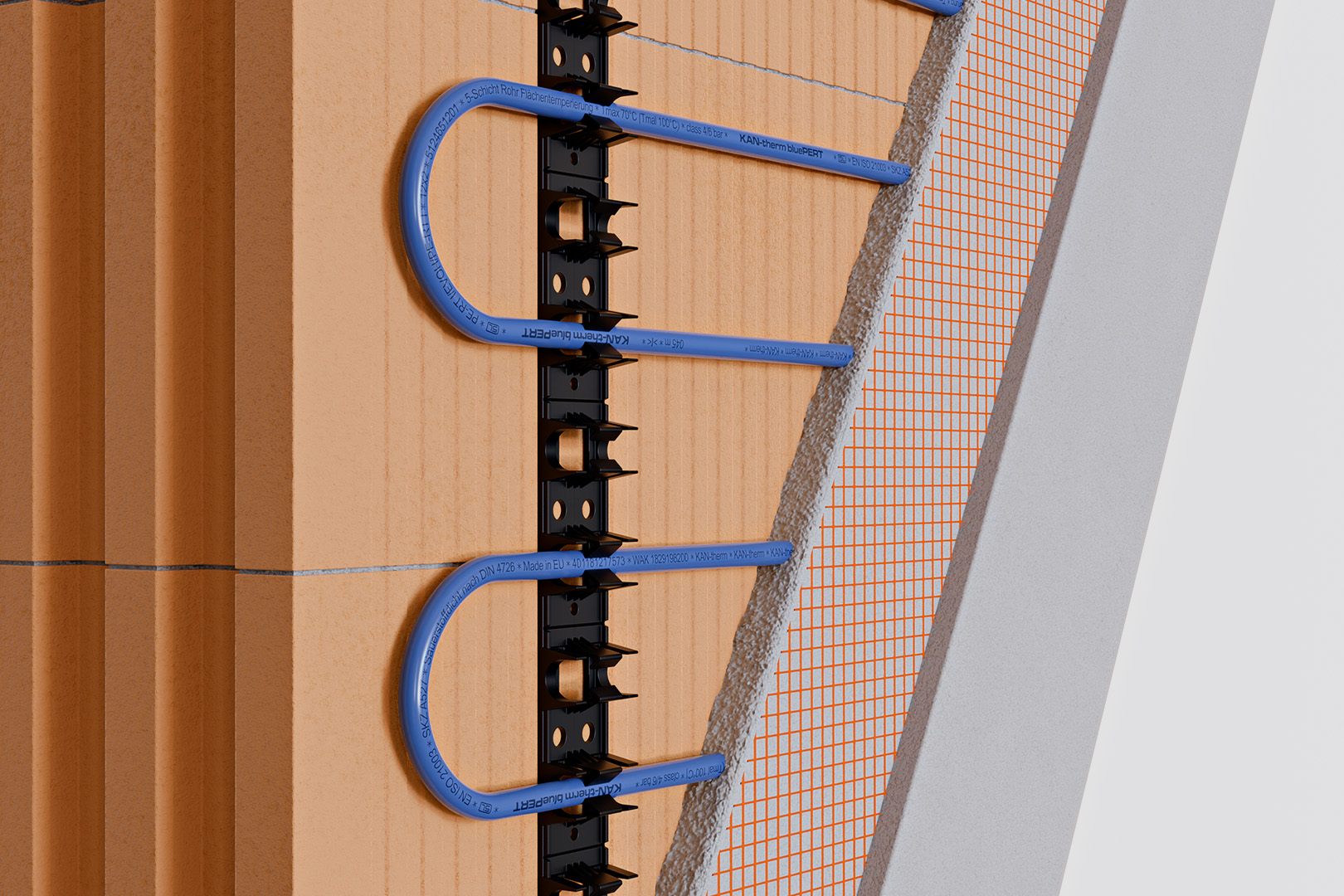

The ultraPRESS fittings are designed for use with PERTAL and bluePERTAL pipes, i.e. pipes with an aluminium layer. KAN designers have also ensured that they are compatible with pipes with an EVOH layer such as bluePERT, PERT and PEXC. The highest quality materials used in the construction of ultraPRESS ensure a very high level of hygiene and aesthetics of the made installations and allow them to work in contact with glycol mixtures. The precise manufacture of the components guarantees their high mechanical strength and the use of special solutions protects against electrochemical corrosion.

One feature unique to the ultraPRESS fittings is controlled leakage, known as LBP (Leak Before Press). This feature makes a poorly pressed-on fitting leak not only during a pressure test, but already while charging the installation system with water. According to the DVGW (German Institute for Standardisation of Plumbing Technology), at least one drop of water per second should appear on an unpressed fitting within the pressure range from 1 to 6 bar. The LBP feature prevents unpressed fittings being left in the system, which can at some point cause a major failure and flooding of the building if the pipe slips out of the fitting under pressure or temperature changes in the pipework.

Note the versatility of KAN-therm ultraPRESS fitting press tool, which is suitable for pressing with two types of jaw profiles: “U” or the more universal “TH”. This is a unique solution in piping systems. The shape of the press-formed sleeve (with a turn-up at the end) ensures precise positioning of the jaw, especially with the “U” jaw profile, where in other systems the jaw can be positioned anywhere, which is a risk of poorly pressed connections.

Design and availability of KAN-therm ultraPRESS fittings

The design of KAN-therm ultraPRESS fittings includes a plastic clamping ring, which acts as a dielectric separator (the aluminium material of the pipe is not in direct contact with the brass of the fitting). In addition, the fittings are available in different colours for quick identification of the diameter and to help avoid confusion when purchasing or picking materials from stock.

Note that the inspection holes provided in the fittings are extremely handy in setting the right insertion depth of the pipe. In some systems where semi-transparent rings are used, visually checking a proper insertion depth can be less convenient, especially when working at low light.

In summary, KAN-therm ultraPRESS system provides the highest quality installation process at a reasonable price.