Glycol is an organic compound that is commonly referred to as antifreeze. There are two main types of glycols: ethylene glycol and propylene glycol. The main difference between the two ones is that ethylene glycol is toxic and propylene glycol is not. Both glycols serve a number of purposes including usage in heating/cooling.

Propylene glycol has become the most common heat transfer fluid used in closed-loop solar heating systems that contain antifreeze.

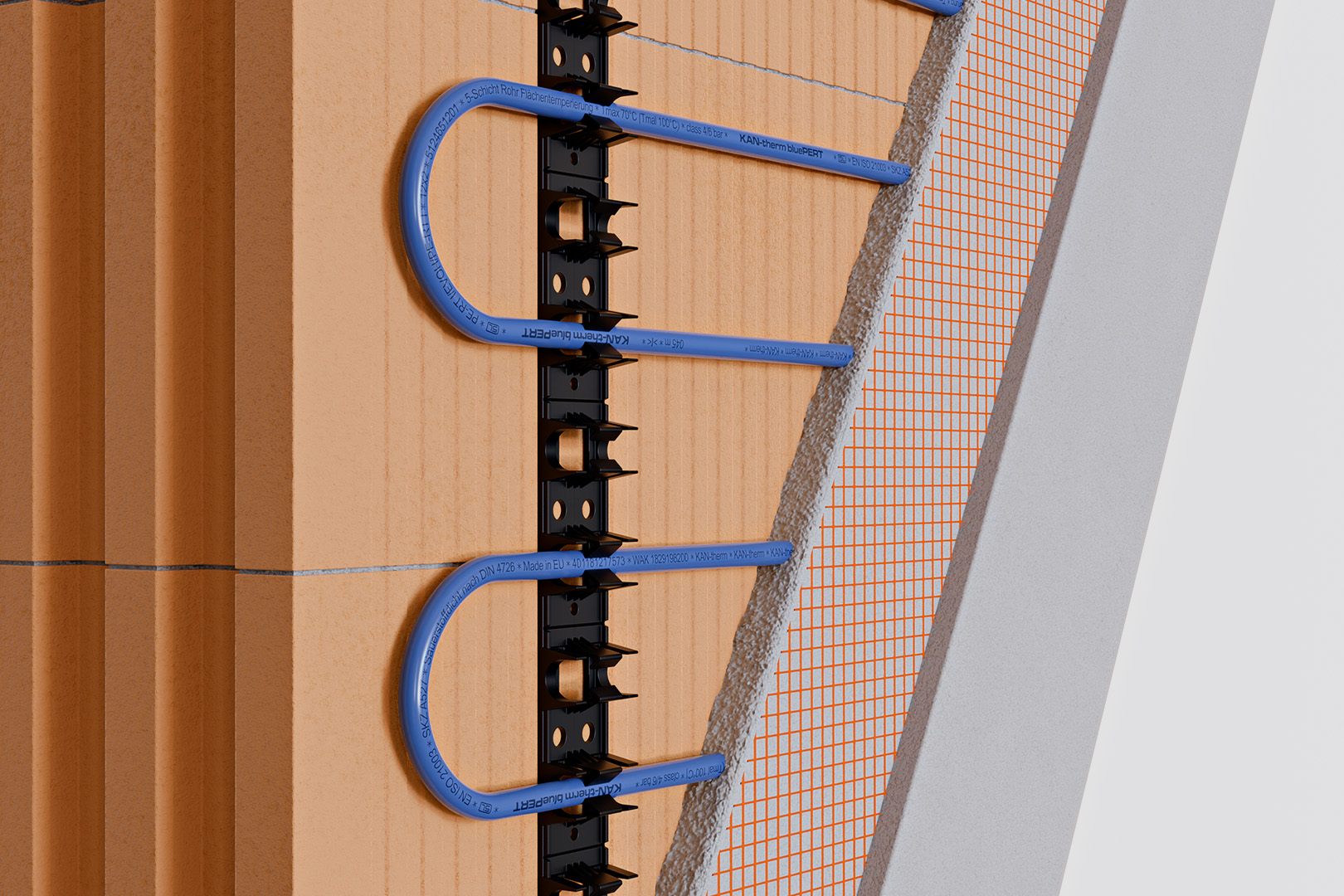

KAN-therm installation can also be filled with propylene glycol (ethylene glycol is prohibited). For example, KAN-therm Steel and Inox systems are a good choice to make installations with solar collectors. In case of filling them with propylene glycol, you should follow some rules to prevent accidents:

- Use only factory-prepared anti-freeze mixtures based on propylene glycol, proved that the recommendations of the mixture manufacturers are followed, including periodic testing of their properties and periodic replacement.

- Do not exceed maximum allowable concentration of propylene glycol in the mixture. It should be not more than 50%. The same concentration is used in KAN-therm ultraLINE, Push, ultraPRESS, PP/PP Green and Surface heating/cooling systems. Note that it should not be more than 35% in KAN-therm Copper and Groove installations.

- For KAN-therm installations use only liquids positively approved by KAN, otherwise they will not be covered by the warranty. Using propylene glycol mixtures in the KAN-therm Copper Gas, Steel Sprinkler and Inox Sprinkler systems are not subjected to KAN warranty either.

- In case of using any mixture that are not included into the KAN list, contact KAN Technical Department for further instructions, how to get KAN approval.

To send an inquiry for approval, one should fill in an Inquiry Application form on our website that is available in the zonePro. To have an access to the zonePro, go through the registration process and create your KAN-therm account. The Fluid Technology Card should also be attached for checking the possibility of using the fluid in KAN-therm systems.

The reason for such a restrictive approach is unacceptable quality of installation fluids available on the market as well as accelerated corrosion of metal elements used in contact with glycol mixtures.

Using high quality propylene glycol mixtures approved by KAN ensures that both installer and user will be satisfied with long and reliable system operation covered by 10-year KAN-therm warranty for KAN-therm systems.