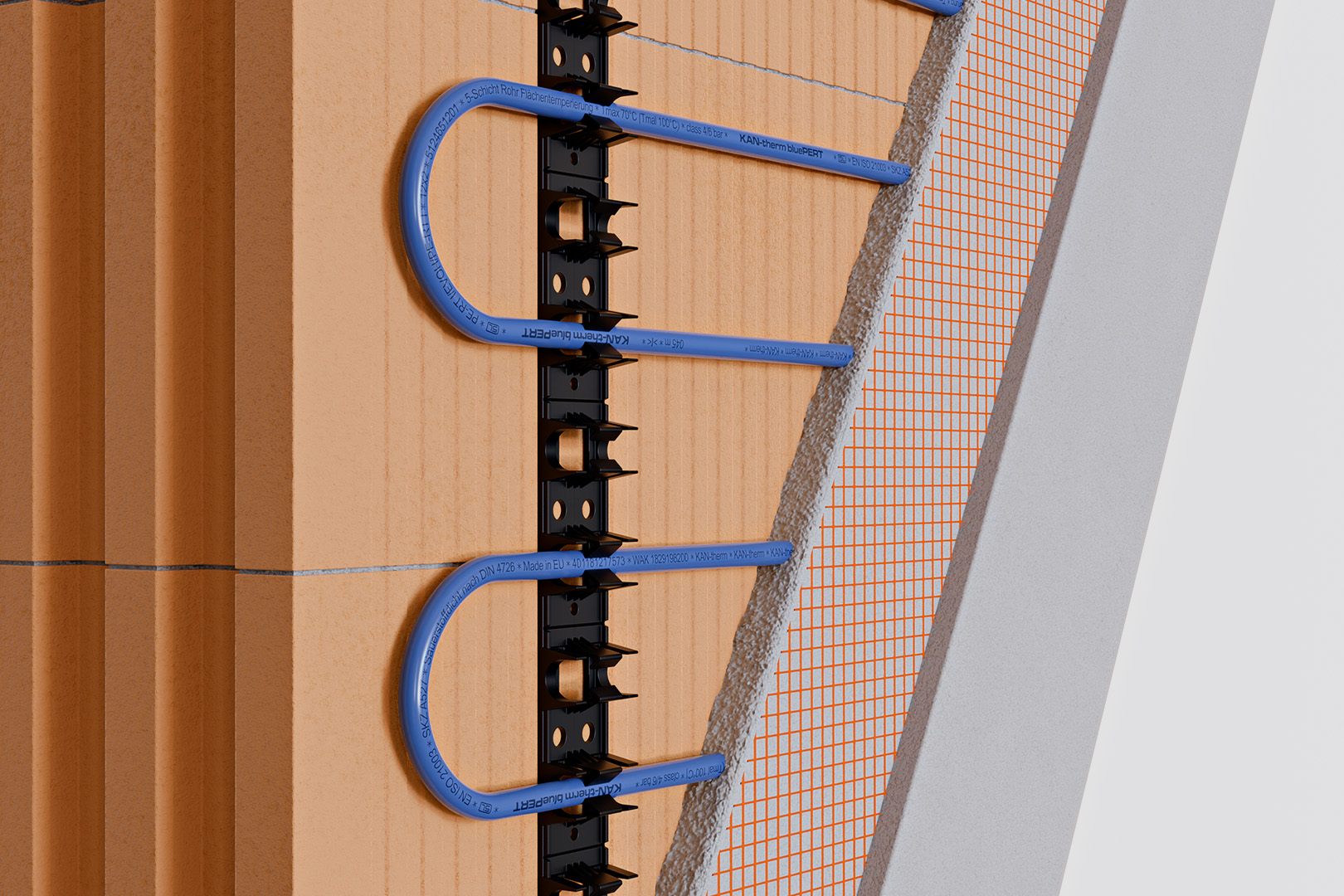

A tacker is a well-known, reliable device used in underfloor heating installations. A tacker in KAN-therm system is a special tool that allows you to quickly and easily fix underfloor heating pipes to an insulation layer, such as polystyrene foam.

It greatly facilitates the work of the installers, allowing them to reduce the execution time of underfloor heating. Thanks to the tacker, the underfloor heating pipes can be precisely positioned and evenly spaced, which contributes to the even distribution of heat in the room.

The construction of a surface radiator composed of KAN-therm Tacker insulation boards is classified (according to the nomenclature of EN 1264) as type A, made using the wet method. Heating pipes are attached to the insulation with plastic clips using a special device, the so-called Tacker (KAN-therm Tacker system), and then flooded with liquid screed. After a period of setting, followed by a curing period, a floor is laid on the screed. The Tacker is used when underfloor heating is being installed, as it enables the clips holding the pipes to be driven into the insulating layer of polystyrene foam. Made of aluminium, the unit is resistant to mechanical damage, so it will remain in impeccable condition for a long time.

We would like to share changes in the KAN-therm Tacker system surface heating offer.

There are several novelties among them. The first one is the modernised tacker tool design.

A new feature of the unit design is the addition of a larger foot, which allows it to maintain a stable position even when it is necessary to take a temporary break from work. We also did not forget to change the way the guide is bent for the clips, so that the clips do not lock onto the guide during operation. In addition, we have made a change to the position of the handle, which has been rotated 180 degrees. The wooden, ergonomic handle has been mounted on a specially shaped metal rod for a secure grip and comfortable working.

The front plate has been refreshed to provide even better identification of the unit with a large logo and the lettering "KAN-therm Tacker" already visible from a distance, guaranteeing its originality. In addition, our product has many other advantages, such as a special screw that allows precise adjustment of the device to virtually any clip width. Adjustments can be made with a regular flat-head screwdriver.

It is worth noting that tackers have adjustable spring tension. It is extremely simple and only requires an Allen spanner to complete. By unscrewing and adjusting the spring tension according to personal preference, comfort can be significantly improved.

The KAN-therm Tacker system has introduced a new type of connecting clips into blocks, which is a recent innovation.

Until now, the clips have been connected by adhesive tape.

The clips currently being introduced into the KAN-therm Tacker system range are joined in the finished block by gently welding the tops together. This definitely increases the durability of the connection between the ready-to-use blocks and the clips.

To summarise, the new features of the KAN-therm Tacker system include:

-quick and easy fixing of underfloor heating pipes to the polystyrene insulation layer,

-significantly simplifying the work of installers,

-shortening the execution time of underfloor heating,

-a new, improved way of joining clips.