Every time when it starts freezing and winter is coming more construction works slow down or stop. Cold season makes us think whether it is possible to install KAN-therm systems at negative temperatures and do not waste precious time.

The answer is yes. We can go on working with KAN-therm installation systems but we should follow some important recommendations to maintain their long-life and reliable operation.

According to general recommendations, assembly of KAN-therm polymer systems should be performed when the outside temperature is above zero. Though it is not a strict rule as an installation process is also possible at external temperature down to -10 degrees.

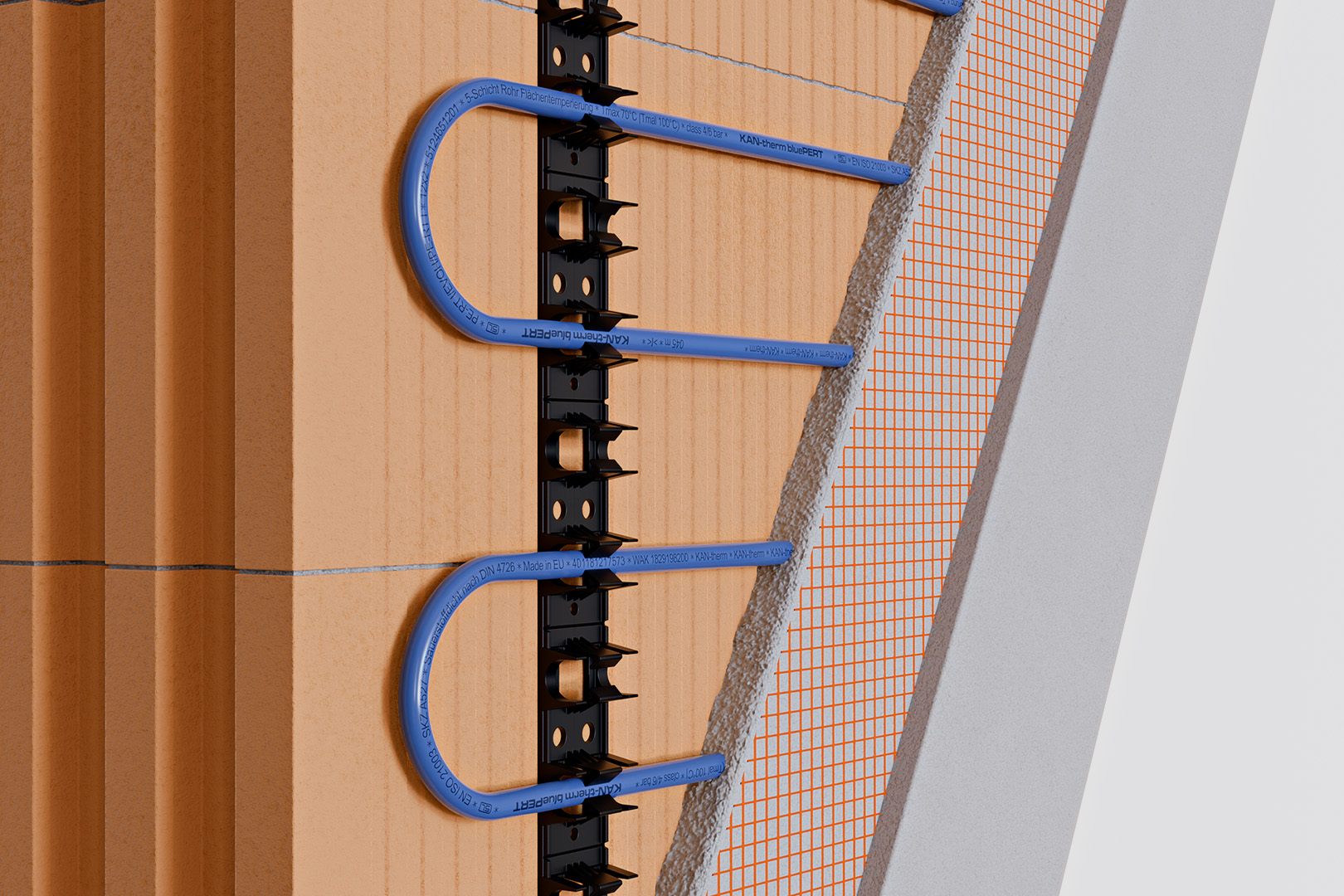

Let us figure out what rules to follow to perform pipe laying works with polyethylene pipes at negative temperatures:

- The cutting tools you are using should have clean and sharp blades without any flaws or chippings, keep cutting perpendicularly to pipe axis.

- Heat the pipe end with hot water or air to restore the pipe elasticity. Never use open fire for pipe heating and monitor the temperature. It must not exceed 90o otherwise the pipe will liquefy.

- Using all polymer pipes and pipes with aluminum layer, you might need to cut off approximately 5 cm of the coiled pipe end. Though there is no need for it in case of pipes supplied in bars.

The above rules are applicable to such KAN-therm systems as ultraLINE, ultraPRESS and PP. In case of PP Glass pipes included in the system KAN-therm PP, pay special attention not to stress the glass fibre mechanically, secure place of welding pipes and fittings from additional wind cooling and comply strictly with 50% time elongation while heating the elements.

Speaking about the installation of the system KAN-therm Steel when the outside temperature is below zero, it is necessary to protect the pipes and fittings from inside condensation that causes corrosion, so the only right way to carry out a test is to use compressed air with the moisture level no more than 880 mg/m³ or with maximum oil concentration level 25 mg/m³.

As you can see, there is no need to stop the building process only because of the weather conditions. KAN-therm systems are at your disposal all year round.

Find more information about the installation process of KAN-therm systems at ambient temperatures below 0°C in The Designer and Constructor Guidebook or contact KAN-therm Technical Department in untypical cases.